Story by Liz Pacheco | Photos by Gene SmirnovRevolution Recovery’s three-and-a-half-acre lot on Milnor Street in Northeast Philadelphia is a shrine to waste. The space hosts a huge pile of used wood and another of drywall. There are stacks of ceiling tiles and bundles of miscellaneous plastic and cardboard. The back of a truck is filled with rolled-up carpets and a group of boxes hold discarded metal poles. A truck pulls up and adds a load of mixed materials—wood, plastic, concrete and metal—to the mess. It’s like being inside a gigantic, well-organized construction site Dumpster.

Story by Liz Pacheco | Photos by Gene SmirnovRevolution Recovery’s three-and-a-half-acre lot on Milnor Street in Northeast Philadelphia is a shrine to waste. The space hosts a huge pile of used wood and another of drywall. There are stacks of ceiling tiles and bundles of miscellaneous plastic and cardboard. The back of a truck is filled with rolled-up carpets and a group of boxes hold discarded metal poles. A truck pulls up and adds a load of mixed materials—wood, plastic, concrete and metal—to the mess. It’s like being inside a gigantic, well-organized construction site Dumpster.

“When people think about waste in general, or they think about recycling, most people think about the bottles and cans and plastic,” says Avi Golen, founder and co-owner of Revolution Recovery. “But really, what’s actually taking up space in our landfills is material produced from manufacturing and construction and demolition.”

In 2003, the U.S. generated more than 160 million tons of construction and demolition waste, reports the Environmental Protection Agency. And of that 160 million tons, only 40 percent was reused, recycled or burned as energy; 60 percent was sent to landfills.

But, Golen and co-owner Jon Wybar don’t see the construction and demolition material at their facility as waste.

“You classify waste as commingled material, mixed material,” says Golen. “So, anytime you mix wood, drywall and cardboard into a Dumpster, people look at it and see waste, where we see commodities just mixed together.”

Their company, Revolution Recovery, is a pioneer in the waste industry. Incorporated in 2004, when green building was just becoming popular, Golen and Wybar’s Revolution Recovery has reinvented the construction waste recycling business. They’ve developed unique ways to handle the materials that typically go straight to landfills. And they’ve set a precedent in the industry, proving that a recycling business fueled by manpower and innovation can not only be economically feasible, but , most importantly, environmentally friendly.

Hands Dirtied

The mission of Revolution Recovery is simple: Keep materials out of landfills. Period. But the seemingly no-brainer mantra is not so easily accepted by others in the construction industry.

In the early 2000s, at the height of the home building boom, Golen was cleaning up home construction sites. Buildings were going up so quickly that there was no real concern about waste, he explains. “As long as there was enough material at the site to keep people moving, it didn’t matter what was trash.”

Golen’s family is in the waste hauling business in Philadelphia, but it wasn’t something Golen was interested in pursuing. After attending college in Colorado, he stayed as a backcountry guide and worked with the nonprofit Telluride Academy, leading kids on backpacking, mountain biking and fly fishing trips. After moving back to Philadelphia and spending time constantly hauling clean, perfectly reusable material to the dump, Golen began to rethink a career in waste.

After doing some research, Golen found drywall recycling was already happening and, according to Wybar, that’s when “he dragged me into it.” The high school friends went for a bike ride and Golen pitched his idea for a construction waste recycling company. Hooked by the idea, Wybar left his job cleaning up The World Trade Center site and joined Golen back in Philadelphia.

At the time, LEED-certified projects were just starting to hit the construction market. LEED (Leadership in Energy and Environmental Design), the green building certification system, had been in development since 1994, but the first standards weren’t released until 2000. When Golen and Wybar started Revolution Recovery, the LEED-certified building business was just emerging. “It was like the Wild West,” says Golen, “No one really knew what they were doing—just figuring it out as you go.” There was a need for construction waste recycling, but no real business model to follow.

The first phone call Golen made in the industry was to Sandy Wiggins, a founder of the then-newly formed Delaware Valley Green Building Council. “When [Golen] came to see me, I was really excited about it,” says Wiggins. “There was really no one in the city thinking about construction waste management.”

Thanks to Wiggins, who was the executive vice president of a construction management company, Golen and Wybar got a job hauling and inventorying waste for a LEED building project. This glorified Dumpster-diving might seemunappealing, but the job provided what Golen describes as “market research.”

“Literally, we started hand-sorting through Dumpsters,” says Golen, “learning what was coming in these Dumpsters and what the makeup of them was.” Next, Golen and Wybar brought separation bins to construction sites, asking for materials to be divided when disposed.

“That was like pushing a really heavy rock uphill,” says Golen. “You’re changing a process that people are so used to… and now you need three Dumpsters on site and it’s not even practical.” With space on urban construction sites limited, having one Dumpster can be challenging, adding two or three more seemed impossible. That’s when Golen and Wybar decided they needed to get into the separation business.

Commodity Brokers

Revolution Recovery’s first site was a small yard where materials were hand-sorted. On Milnor, materials are still hand-sorted, but are paraded through the upper floor of the warehouse on a massive conveyor belt. Waste is source-separated (essentially divided by type of material) and dropped into individualized areas that resemble one-car garages.

During the summer, their high season, Revolution Recovery takes in an average 150-200 tons a day. Compared with larger waste businesses, this number is tiny. Transfer stations nearby will take in three times that amount, with everything going to the landfill.

At a traditional waste transfer station, for every pound that comes in, one goes out. “They just have two guys and they’re both in huge machines,” says Wybar. “The truck dumps, they just push it. Everything goes to the landfill.” In these operations, most money is spent getting waste to the landfill; labor costs are low. For Revolution Recovery, the equation is reversed.

“We’re pulling every little piece of this and that,” says Wybar. “We have 40 different products going out, so we’re spending tons on labor and machinery.” And much less is going to the landfill. For every 5 tons received, Revolution Recovery has a full-time job. According to Wybar, at a regular waste transfer station, the ratio is about 300 tons per full-time job.

Staying cost-competitive is important, so every bit of waste counts. In a landfill, a pound is a pound, no matter if it’s gold or cardboard. For Revolution Recovery, everything is a commodity that can be reused and recycled.

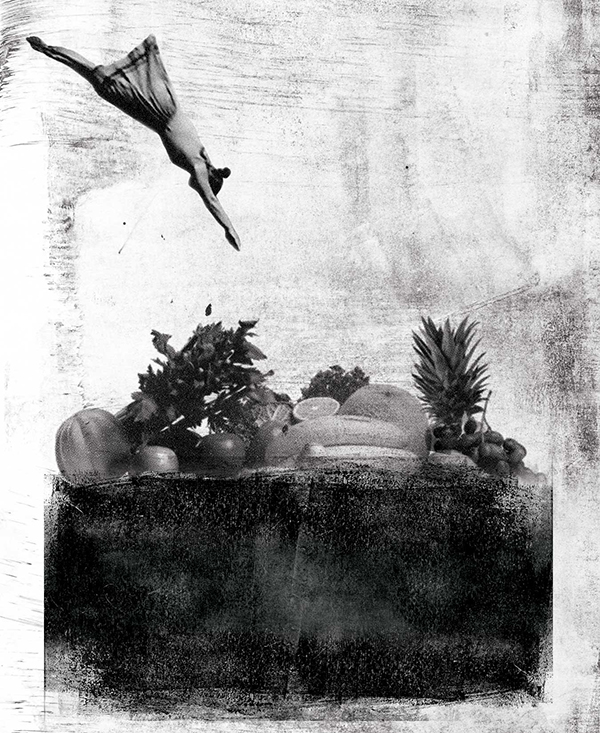

Wood is their most popular material. Pieces are first pulled out for nonprofits and art groups, like RAIR, an artist-in-residency program working at Revolution Recovery (see above). The rest is made into mulch onsite. Wood that can’t be mulched becomes a fuel chip product. Rubble, which includes brick, concrete, asphalt and the like, is also crushed onsite. The resulting product is used for road base, drainage fill projects and paving.

Most other waste Revolution Recovery takes in is only minimally processed or packaged, then sent elsewhere to be fully recycled. For example, drywall is consolidated, then shipped to a processor and ground into a soil, fertilizer and conditioner product. Ceiling tiles are returned to the manufacturer and made into new tiles. A similar process happens with carpets. Some materials, like insulation, can’t be recycled and are sent to a waste energy facility or a landfill.

While much of the market for separated products has been around for some time—like the scrap metal and paper and cardboard recycling businesses—Revolution Recovery is pushing manufacturers to take waste recycling a step further. Revolution Recovery is working with Mannington, a flooring company, to take some recycled drywall and incorporate it into flooring products. And Armstrong World Industries is taking back their ceiling tile.

“We’re constantly doing more and more research on what we can do to upgrade the value of this waste,” says Golen. “Whether it’s sorting it one step further… or if we had the room, we could take our plastics and instead of sending it to a plastic recycler… grind it and clean it here.”

Ahead of the Field

Scott Kelly, co-founder of Re:Vision, a Philadelphia- and Berkley, Calif.-based sustainable architecture, planning and consulting firm, has worked with Revolution Recovery on various projects. “I’ve been able to go to them with materials others have struggled with,” says Kelly. “I’ve seen them develop special techniques[for recycling and reusing materials].”

Kelly recognizes Revolution Recovery as forerunners in the industry and explains their business model as simply an invention of new ways for doing everything in the construction waste business. “They looked in a Dumpster and said, ‘How can I find a use for this?’ not ‘How can I get rid of this?’”

“I would say that they’re pioneers in construction waste management,” says Wiggins, “not just regionally, but across the country.”

And, as Wiggins explains, the market for green building is only growing. Recycling construction waste is becoming mainstream and more waste companies are adapting their ways.

“Five years ago it was tricky, we were still developing outlets. Now it’s kind of even or we [have traditional waste companies] on the run a little,” says Wybar. “I think in five or 10 years, if you’re not recycling, you won’t be in business because you won’t be able to compete.”

For more information on Revolution Recovery and the materials they recycle visit revolutionrecovery.com

Go get it Jonny!